The MG

The MGB was in production for 18 years, during which time over 500,000 examples were produced. They remain a popular car and are the most numerous model in the MG Car Club. They are a relatively simple car, with excellent parts availability. They are DIY friendly and are not difficult for a home mechanic to work on.

Here's my 1979 MGB

The top and covers are in perfect shape

It is in really good shape

And it is all original

| INTERIOR The interior of MGB’s is fairly simple, and the good news is that virtually anything is now available.

|

29,000 original miles on it and the engine is clean

Sitting here in Valley View Ohio, isn't it cute?

The engine in all MGB’s is the BMC “B Series” 4 cylinder engine. The engine is cast iron in construction and is overhead valve with a capacity of 1798cc and a stated power output of 95bhp. This engine had already been in production in 1500 and 1600cc versions prior to being enlarged to 1800cc for the MGB.

The B Series is not a particularly quiet engine, and there will always be an element of tappet noise even on a good engine. If you hear an engine that is totally silent, it may have had the tappets adjusted up to hide wear.

$8750

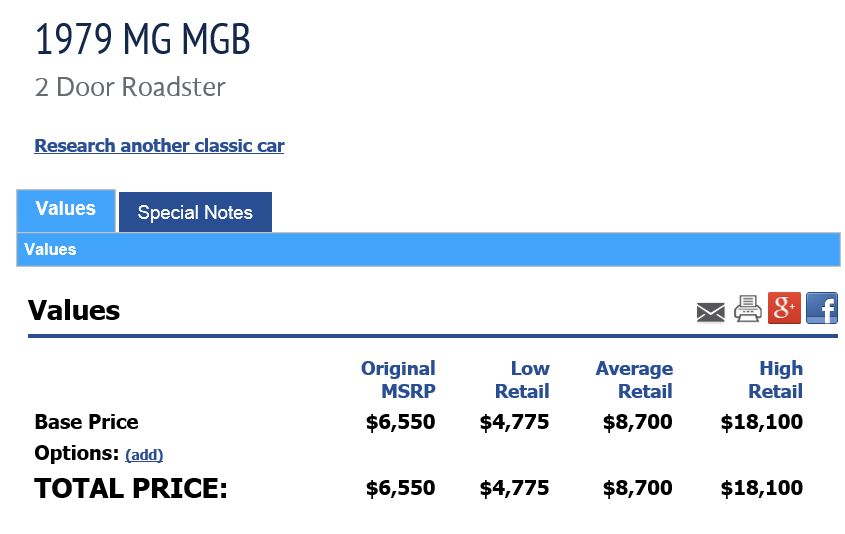

Check out the NADA value guide for this or other classic cars

For current pricing, enter the following into your browser: https://www.NADAGUIDES.com/cars/1979/MG/MGB or click the LOGO Below

The bodywork is the most important factor to look for when buying an MGB. As these cars now range from 27-45 years old, virtually all will have had some panel work done and some rust removal or paintwork. The standard of care of the car and the standard of repairs performed will have a significant impact on how the car has lasted. The body is the most expensive area of the car to put right and accordingly is the critical area to view when considering a purchase.

The MGB was the first MG sports car to have a monocoque construction, i.e. a single bodyshell with no separate chassis. The bodyshell was somewhat over engineered, and is exceptionally strong and well constructed. However, rust prevention was not as advanced as it is today, and accordingly it is important to ensure the car you are viewing is structurally sound.

The key area to check for corrosion on an MGB is the sills. The sills run from the back of the front wheelarch to the start of the rear wheelarch and form the main structural strength of the car, and accordingly are very important. The outer section of the sill that is visible from the exterior has within it a central membrane, with an inner box section inside that. You should ensure there is no corrosion visible inside, outside or underneath the car in the area of the sills. Note that sometimes minor rust bubbles visible at the front or back of the sill may simply be corrosion in the outer panels, which is not critical but should be attended to before it spreads. However, this often cannot be determined without expert scrutiny, so treat any visible sill rust with suspicion. If complete sill replacement is needed, the work should be carried out by someone experienced in this job, as correct alignment is vital.

While you are inside the car checking sills, lift the carpets and ensure the floors are sound. Also lift the carpets at the back of the cabin to check for any corrosion. If possible, remove the battery covers (the batteries are located in metal cages below the rear floor) to ensure that the battery boxes have not corroded. Note that until 1975 MGB’s had twin six volt batteries, and after that moved to a single twelve volt battery which resulted in the nearside battery box being removed.

The front wings should be checked next. Look for corrosion at the base of the wing, in the seam where the wing joins the scuttle, and around the headlights. Minor corrosion can also occur where the side trim strips are held on to the wing. A useful check is to reach inside the inner wing near the back, where you will find a small ledge; the top of this ledge can gather road dirt and hence can corrode, so a check with your hand is worthwhile.

Moving back, check the base of the doors and underneath the doors for corrosion and ensure the drain holes in the door bottoms are clear and free of rust. Ensure the door fit is good and that the doors open and close easily. Looking at the rear wings, check the wheelarches carefully and run your hand inside the rear wheelarch rim to check for filler or rust. The seam at the top of the rear wing should also be checked.

At the rear of the car, check the boot floor for corrosion and also ensure there is no evidence of fuel leaks from the top of the fuel tank, which can corrode (look for fuel leaks or smells).

All of the exterior trim should also be checked for damage, though replacement of these items is relatively simple and not particularly expensive.